The making of a Bayntun-Riviere binding

Forwarding

Initially the book is collated before the covers are removed and the pages unpicked. Any necessary cleaning and paper repairs are carried out at this stage. Each section of the book is then sewn by hand onto linen cords, which give the book flexibility and strength. After the book block has been sewn, endpapers which have been chosen to complement the binding are then attached.

The sections which form the spine are then brushed with glue, before being knocked flat and left to dry. The spine is then rounded with a hammer and clamped into a hand-operated ‘backing’ machine which forms the ‘shoulders’ of the book, in preparation for board attachment. Conservation millboard is used to form the covers, which are attached by fraying and then lacing in the cords from the sewn book block. The books are then stacked in a standing press and left overnight.

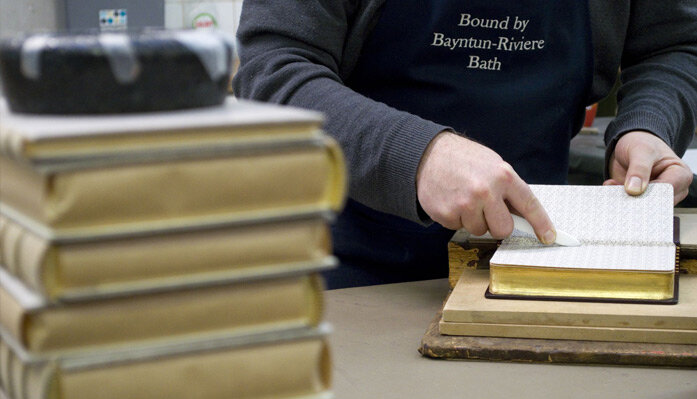

If the edges of the book require gilding then the page edges must now be trimmed on a guillotine. The book is then held in a gilding press and the pages are sanded to give a smooth finish prior to the application of gold.

We gild all of our books by hand using 23½ carat gold leaf. Gilding helps to protect the pages against moisture and dust, as well as enhancing the appearance of the binding. Armenian bole (a fine red clay) is mixed with paste and then applied to provide a base for the gold leaf. Glair (a mixture of egg albumen and water) is then brushed carefully onto the edges for the gold to adhere to. The gold leaf is cut to size and applied using a ‘gilders tip’ (a squirrel hair brush). Once the glair is sufficiently dry the gold is ready to be polished with an agate burnishing tool. During the polishing process, beeswax is applied to the edges in order to provide a smooth surface for the burnisher.

After gilding, the headbands are sewn by hand using colourful silk threads. These make up the difference in size between the page sections and the boards, as well as decorating and strengthening the headcap of the book.

The next stage is to ‘line up’ the spine and make a hollow back which allows the book to open easily. Firstly, a strip of mull (linen gauze) is glued to the spine followed by a sheet of unglazed kraft paper. Then an additional piece of paper is attached before being folded back and forth, creating the hollow back. If decorative bands are required, they are glued on at this stage.

Once a suitable skin of leather has been chosen, it is carefully cut to size and the edges are pared with a French paring knife in preparation for covering. The leather is first slightly dampened with a sponge before being pasted and ‘drawn onto’ the spine. It is moulded tightly over the spine and then gently eased across the boards. After the corners are trimmed and mitred, the remaining leather is turned in over the inside boards and tucked into the hollow back to create the headcaps. The decorative bands on the spine are then shaped with a pair of band nippers. Once covering is complete, the book is then left open to dry for approximately an hour, before being closed and placed under a weight. After twenty-four hours the book is opened up, the inside boards are filled in with acid-free card and the book is left to dry for a further week before finishing.

Finishing

The final stage in binding a book is known as ‘finishing’, where heated tools are used to letter and decorate the book in gilt or blind. Firstly, the leather is polished and sealed with a heated polishing iron. The spine and covers are carefully washed over with water before being left to dry. Tooling is initially impressed in blind, before glair is brushed over the tooled area. The surface is now ready for the gold to be applied and the tooling repeated. At this point it is vital that the heat and amount of pressure is judged correctly, avoiding any damage to the leather. For designs which are too large to be tooled by hand, a heated blocking press is used to impress engraved brass or zinc blocks onto the leather. Once finishing is complete, the endpapers can be pasted down before the book is gently polished and pressed for the final time.